Location

CoLab, COM 100

Start Date

1-5-2025 5:30 PM

Document Type

Poster

Description

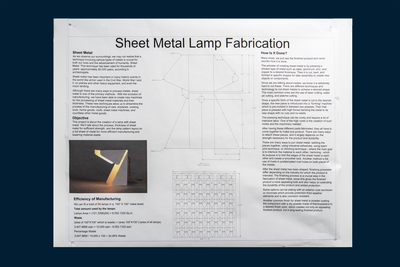

As we observe our surroundings, we may not realize that a technique involving various types of metals is crucial for both our lives and the advancement of humanity. Sheet Metal: This technique has been used for thousands of years; approximately 80,000 years, according to archeologists. Sheet metal has been important in many historic events in the world like armor used in the Civil War, World War I and II, on planes and other heavy equipment, and even the moon landing. Although there are many ways to process metals, sheet metal is one of the primary methods. With the evolution of manufacturing, we have been able to create new machines for the processing of sheet metal materials and their thickness. These new techniques allow us to streamline the process of the manufacturing of cars, airplanes, cooking tools, home goods, roofs, sheet metal machines, and countless other metal goods. This project is about the creation of a lamp with sheet metal. We’ll talk about the process, thickness of sheet metal for sufficient strength, and the lamp pattern layout on a full sheet of metal for more efficient manufacturing and lowering material waste.

Sheet Metal Lamp Project

CoLab, COM 100

As we observe our surroundings, we may not realize that a technique involving various types of metals is crucial for both our lives and the advancement of humanity. Sheet Metal: This technique has been used for thousands of years; approximately 80,000 years, according to archeologists. Sheet metal has been important in many historic events in the world like armor used in the Civil War, World War I and II, on planes and other heavy equipment, and even the moon landing. Although there are many ways to process metals, sheet metal is one of the primary methods. With the evolution of manufacturing, we have been able to create new machines for the processing of sheet metal materials and their thickness. These new techniques allow us to streamline the process of the manufacturing of cars, airplanes, cooking tools, home goods, roofs, sheet metal machines, and countless other metal goods. This project is about the creation of a lamp with sheet metal. We’ll talk about the process, thickness of sheet metal for sufficient strength, and the lamp pattern layout on a full sheet of metal for more efficient manufacturing and lowering material waste.

Comments

The faculty mentor for this project was Susan Johnson, Engineering.