Location

CoLab, OCB 100

Start Date

25-4-2024 6:00 PM

Document Type

Poster

Description

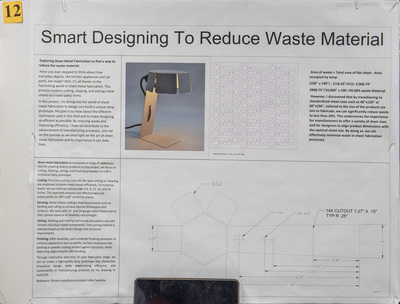

Sheet metal fabrication is a fascinating process that underpins the creation of everyday items like kitchen appliances and car parts. In this project, I delve into this world to design and construct a unique lamp prototype, aiming to showcase various fabrication techniques and optimize the design process for efficiency. By minimizing waste and improving efficiency, my goal is to contribute to the advancement of manufacturing processes. Join me on this journey as we illuminate the art of sheet metal fabrication and its significance in our daily lives. Sheet metal fabrication involves cutting, forming, joining, and finishing processes essential for crafting diverse products. Precision cutting methods such as laser cutting and shearing are used to divide metal sheets efficiently. To reduce waste, we employ nominal cutting sizes of 6, 8, 12, 16, and 24 inches, ensuring cost-effectiveness and sustainability for 48”x 120” metal flat sheets. Metal sheets undergo shaping processes like bending and rolling to achieve desired dimensions and contours. We work with 22- and 24-gauge metal sheets due to their optimal balance of flexibility and strength. Welding and riveting techniques securely connect individual metal components, selected based on the lamp's design and structural requirements. After assembly, parts undergo finishing processes to enhance appearance and durability. Surface treatments like painting or powder coating protect against corrosion, while deburring edges ensures safe handling. Through meticulous execution of each fabrication stage, our aim is to create a high-quality lamp prototype that showcases innovative design while emphasizing efficiency and sustainability in manufacturing practices. References: Elevate manufacture product data/https://www.holcimbe.com/en

Exploring Sheet Metal Fabrication to Find a Way to Reduce the Waste Material: Designing a Functional Lamp

CoLab, OCB 100

Sheet metal fabrication is a fascinating process that underpins the creation of everyday items like kitchen appliances and car parts. In this project, I delve into this world to design and construct a unique lamp prototype, aiming to showcase various fabrication techniques and optimize the design process for efficiency. By minimizing waste and improving efficiency, my goal is to contribute to the advancement of manufacturing processes. Join me on this journey as we illuminate the art of sheet metal fabrication and its significance in our daily lives. Sheet metal fabrication involves cutting, forming, joining, and finishing processes essential for crafting diverse products. Precision cutting methods such as laser cutting and shearing are used to divide metal sheets efficiently. To reduce waste, we employ nominal cutting sizes of 6, 8, 12, 16, and 24 inches, ensuring cost-effectiveness and sustainability for 48”x 120” metal flat sheets. Metal sheets undergo shaping processes like bending and rolling to achieve desired dimensions and contours. We work with 22- and 24-gauge metal sheets due to their optimal balance of flexibility and strength. Welding and riveting techniques securely connect individual metal components, selected based on the lamp's design and structural requirements. After assembly, parts undergo finishing processes to enhance appearance and durability. Surface treatments like painting or powder coating protect against corrosion, while deburring edges ensures safe handling. Through meticulous execution of each fabrication stage, our aim is to create a high-quality lamp prototype that showcases innovative design while emphasizing efficiency and sustainability in manufacturing practices. References: Elevate manufacture product data/https://www.holcimbe.com/en

Comments

The faculty mentor for this project was Susan Johnson, Engineering.