Location

CoLab, OCB 100

Start Date

25-4-2024 6:00 PM

Document Type

Poster

Description

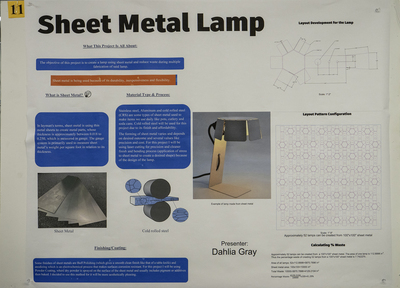

The objective of this project is to create a lamp using sheet metal and reduce waste during multiple fabrication of said lamp. Sheet metal is being used because of its durability, inexpensiveness and flexibility. In layman's terms, sheet metal is using thin metal sheets to create metal parts, whose thickness is approximately between 0.018 to 0.250, which is measured in gauge. The gauge system is primarily used to measure sheet metal’s weight per square foot in relation to its thickness. Stainless steel, Aluminum and cold rolled steel (CRS) are some types of sheet metal used to make items we use daily like pots, cutlery and soda cans. Cold rolled steel will be used for this project due to its finish and affordability. The forming of sheet metal varies and depends on desired outcome and several values like precision and cost. For this project I will be using laser cutting for precision, cleaner finish and bending process (application of stress to sheet metal to create a desired shape) because of the design of the lamp. Some finishes of sheet metals are Buff Polishing (which gives a smooth clean finish like that of a table knife) and anodizing which is an electrochemical process that makes surfaces corrosion resistant. For this project I will be using Powder Coating, where dry powder is sprayed on the surface of the sheet metal and usually includes pigment or additives then baked. I decided to use this method for it will be more aesthetically pleasing.

Sheet Metal Fabrication-Lamp

CoLab, OCB 100

The objective of this project is to create a lamp using sheet metal and reduce waste during multiple fabrication of said lamp. Sheet metal is being used because of its durability, inexpensiveness and flexibility. In layman's terms, sheet metal is using thin metal sheets to create metal parts, whose thickness is approximately between 0.018 to 0.250, which is measured in gauge. The gauge system is primarily used to measure sheet metal’s weight per square foot in relation to its thickness. Stainless steel, Aluminum and cold rolled steel (CRS) are some types of sheet metal used to make items we use daily like pots, cutlery and soda cans. Cold rolled steel will be used for this project due to its finish and affordability. The forming of sheet metal varies and depends on desired outcome and several values like precision and cost. For this project I will be using laser cutting for precision, cleaner finish and bending process (application of stress to sheet metal to create a desired shape) because of the design of the lamp. Some finishes of sheet metals are Buff Polishing (which gives a smooth clean finish like that of a table knife) and anodizing which is an electrochemical process that makes surfaces corrosion resistant. For this project I will be using Powder Coating, where dry powder is sprayed on the surface of the sheet metal and usually includes pigment or additives then baked. I decided to use this method for it will be more aesthetically pleasing.

Comments

The faculty mentor for this project was Susan Johnson, Engineering.