Location

CoLab, OCB 100

Start Date

25-4-2024 6:00 PM

Document Type

Poster

Description

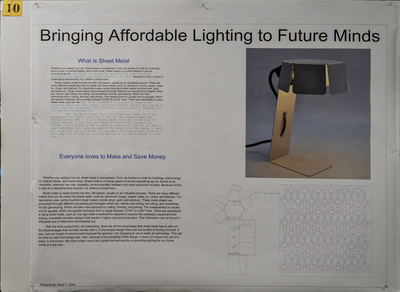

Whether you realize it or not, sheet metal is everywhere. From car bodies to roofs for buildings, plane wings to medical tables, and much more. Sheet metal is a critical aspect of almost everything we do, thanks to its versatility, relatively low cost, durability, environmentally resistant and rapid production of parts. Because of this, it pays to understand what exactly it is, where it comes from. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. There are many different metals that can be made into sheet metal, such as: aluminum, brass, copper, steel, tin, nickel, and titanium. For decorative uses, some important sheet metals include silver, gold, and platinum. These metal sheets are processed through different processing technologies which are, mainly cold rolling, hot rolling, and sometimes hot dip galvanizing. Which are then manufactured by cutting, forming, and joining. The measurement is usually sort by gauges, which are specific thickness form a range between 0.018’’ to 0.250’’ thick. There are drawbacks in using sheet metal, such as, the high initial investment is required to acquire the necessary equipment and tooling, unsuitable complex designs that results in higher cost and production. This information can be found in Wikipedia and at https:www.servicesteel.org. With the lamp project that I am presenting there are all the advantages that sheet metal has to without the disadvantages that normally comes with it. In this simple design there will not be allot of tooling involved. It also, has low impact on environment because the process I am choosing to use is water jet technology. Because I tend to use an already established company with all the necessary equipment the cost should be lower for initial design. Also, because of the simplicity of the design, it does not require the use of a press. In conclusion, this lamp project would be a great low-cost solution to providing lighting for students at a more than reason cost.

Lamp Project

CoLab, OCB 100

Whether you realize it or not, sheet metal is everywhere. From car bodies to roofs for buildings, plane wings to medical tables, and much more. Sheet metal is a critical aspect of almost everything we do, thanks to its versatility, relatively low cost, durability, environmentally resistant and rapid production of parts. Because of this, it pays to understand what exactly it is, where it comes from. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. There are many different metals that can be made into sheet metal, such as: aluminum, brass, copper, steel, tin, nickel, and titanium. For decorative uses, some important sheet metals include silver, gold, and platinum. These metal sheets are processed through different processing technologies which are, mainly cold rolling, hot rolling, and sometimes hot dip galvanizing. Which are then manufactured by cutting, forming, and joining. The measurement is usually sort by gauges, which are specific thickness form a range between 0.018’’ to 0.250’’ thick. There are drawbacks in using sheet metal, such as, the high initial investment is required to acquire the necessary equipment and tooling, unsuitable complex designs that results in higher cost and production. This information can be found in Wikipedia and at https:www.servicesteel.org. With the lamp project that I am presenting there are all the advantages that sheet metal has to without the disadvantages that normally comes with it. In this simple design there will not be allot of tooling involved. It also, has low impact on environment because the process I am choosing to use is water jet technology. Because I tend to use an already established company with all the necessary equipment the cost should be lower for initial design. Also, because of the simplicity of the design, it does not require the use of a press. In conclusion, this lamp project would be a great low-cost solution to providing lighting for students at a more than reason cost.

Comments

The faculty mentor for this project was Susan Johnson, Engineering.