Location

CoLab, OCB 100

Start Date

25-4-2024 12:00 PM

Document Type

Poster

Description

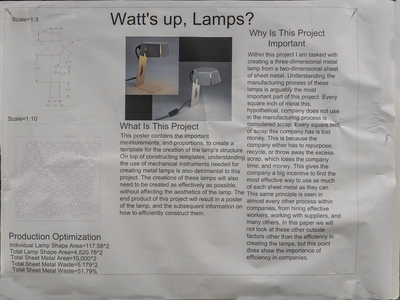

This poster contains the important measurements, and proportions, to create a template for the creation of the lamp's structure. On top of constructing templates, understanding the use of mechanical instruments needed for creating metal lamps is also detrimental to this project. The creations of these lamps will also need to be created as effectively as possible, without affecting the aesthetics of the lamp. The end product of this project will result in a poster of the lamp, and the subsequent information on how to efficiently construct them. The lamp blueprint corresponds to the dimensions of the lamp that is produced out of flat sheet metal. Once the shape of the metal is punched out with a special shaped die, and punch, the metal is shaped, and formed to our desired lamp form. The creation of this lamp is very similar to how a car fender would be shaped, and formed. A car fender is cut from a sheet of steel in one piece. The flat steel blank is then shaped, and formed to be both, more structurally strong, and to conform to the body of a car. Within this project I am tasked with creating a three-dimensional metal lamp from a two-dimensional sheet of sheet metal. Understanding the manufacturing process of these lamps is arguably the most important part of this project. Every square inch of metal this, hypothetical, company does not use in the manufacturing process is considered scrap. Every square inch of scrap this company has is lost money. This is because the company either has to to repurpose, recycle, or throw away the excess scrap, which loses the company time, and money. This gives the company a big incentive to find the most effective way to use as much of each sheet metal as they can. This same principle is seen in almost every other process within companies, from hiring effective workers, working with suppliers, and many others. In this paper we will not look at these other outside factors other than the efficiency in creating the lamps, but this point does show the importance of efficiency in companies.

Sheet Steel Lamp

CoLab, OCB 100

This poster contains the important measurements, and proportions, to create a template for the creation of the lamp's structure. On top of constructing templates, understanding the use of mechanical instruments needed for creating metal lamps is also detrimental to this project. The creations of these lamps will also need to be created as effectively as possible, without affecting the aesthetics of the lamp. The end product of this project will result in a poster of the lamp, and the subsequent information on how to efficiently construct them. The lamp blueprint corresponds to the dimensions of the lamp that is produced out of flat sheet metal. Once the shape of the metal is punched out with a special shaped die, and punch, the metal is shaped, and formed to our desired lamp form. The creation of this lamp is very similar to how a car fender would be shaped, and formed. A car fender is cut from a sheet of steel in one piece. The flat steel blank is then shaped, and formed to be both, more structurally strong, and to conform to the body of a car. Within this project I am tasked with creating a three-dimensional metal lamp from a two-dimensional sheet of sheet metal. Understanding the manufacturing process of these lamps is arguably the most important part of this project. Every square inch of metal this, hypothetical, company does not use in the manufacturing process is considered scrap. Every square inch of scrap this company has is lost money. This is because the company either has to to repurpose, recycle, or throw away the excess scrap, which loses the company time, and money. This gives the company a big incentive to find the most effective way to use as much of each sheet metal as they can. This same principle is seen in almost every other process within companies, from hiring effective workers, working with suppliers, and many others. In this paper we will not look at these other outside factors other than the efficiency in creating the lamps, but this point does show the importance of efficiency in companies.

Comments

The faculty mentor for this project was Susan Johnson, Engineering.